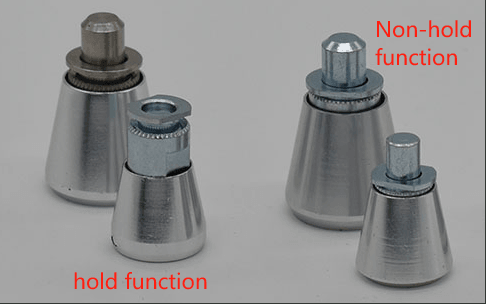

A spring plunger is a simple positioning mechanism whose functions can be categorized into two types: hold and non-hold.

1. Hold Function: Typically used when the mechanism is locked in the stopped position. Under external force, it maintains a retracted state while allowing the mechanism to move. If the external force is removed, it remains retracted, and the mechanism reverts to the locked state.

2. Non-Hold Function: Typically employed when the mechanism is locked in place. Under external force, it maintains a retracted state while allowing the mechanism to move. If the external force ceases, the mechanism immediately returns to the locked state.

2. Non-Hold Function: Typically employed when the mechanism is locked in place. Under external force, it maintains a retracted state while allowing the mechanism to move. If the external force ceases, the mechanism immediately returns to the locked state.

Common Materials for Spring Plungers

Based on functional requirements, we can customize various sizes and designs to meet specific structural specifications. We also recommend different spring plunger materials according to the customer's load and environmental conditions.

Materials: Standard options include stainless steel 303, 304, and 316; carbon steel; and aluminum alloy.

Surface Treatments: Stainless steel passivation; carbon steel heat treatment; blue-white zinc plating; and aluminum alloy oxidation.

FAQ

Question 1:

How to select the material and machining process for spring plunger based on load weight?

Question 2:

How to set the fit tolerances between the spring plunger body and the mounting hole?

Question 3:

How should the spring plunger be installed?

Question 4:

What are the installation methods for spring plungers?